- Have any questions?

- +91 22 6639 3788

- +91 22 6636 3360

- info@kanakmetals.com

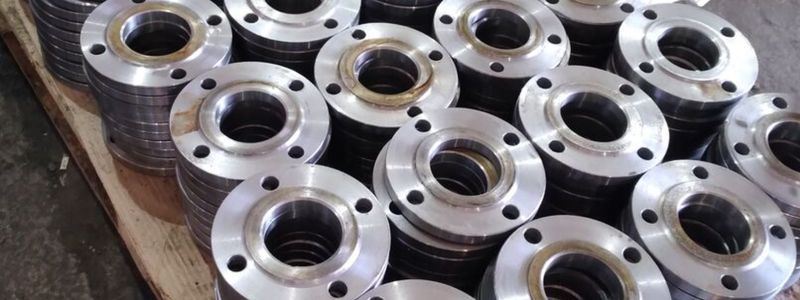

Flanges Manufacturer & Supplier in Wada MIDC, India

Flanges Manufacturer & Supplier in Wada MIDC, India – Kanak Metal & Alloys

Kanak Metal & Alloys is a leading Flanges Manufacturer in Wada MIDC, India. Flanges can be threaded or welded, and by attaching two together with gaskets, you can make a seal that makes it simple to access the pipe system. Our Flanges are developed in accordance with national and international standards. Flanges Supplier in Wada MIDC work with various suppliers to ensure that they have a vast inventory of fittings available for immediate delivery to their customers.

Flanges Manufacturer, Socketweld Flanges Supplier, Blind Flanges Exporter, Slip-On Stockist in Wada MIDC, India

One of the most important things to look for when selecting a Flanges manufacturer is the quality of their Flanges. Users want to be certain that the Socketweld Flanges are made from high-quality materials and are correctly finished. Another element to consider when selecting a Slip-On Flanges manufacturer is their level of experience. You should ensure that the manufacturer has vast expertise in making Flanges so that you may have confidence in their ability to deliver a high-quality product.

Flange is widely used due to its high corrosion resistance and weldability. Flanges Manufacturer in Wada MIDC ensure that they have a good understanding of customer needs to provide high-quality products that meet the required industry standards. Our Flanges manufacturers supply these flanges in various grades & materials, such as Stainless Steel, Carbon Steel, Alloy Steel, Duplex Steel, Super Duplex Steel, Inconel, Monel, and Hastelloy, based on the needs of the customer. We are also a Leading Flanges Manufacturer in Kutch GIDC, India.

Top Selling of Flanges Types:

There are many different types of flanges, each with its own unique specifications. When choosing a flange, you must consider the size, material, and pressure rating of the pipe it will be connecting to.

Flanges Grades, Sizes & Specifications:

Flanges are available in a variety of grades and specifications to meet the needs of any project. Flanges Supplier in Wada MIDC ensure that they have a good understanding of customer needs to provide high quality products that meet the required industry standards.

| Flanges | Specifications |

|---|---|

| Type of Flanges | Slip-On, Weld Neck, Long Weld Neck, Threaded, Blind, Companion, Lap Joint. |

| Size | 1/2″ (15 NB) to 48″ (1200NB) DN10~DN5000. |

| Type | Raised Face (RF), Flat Face (FF), Ring Type Joint (RTJ), Lap-Joint Face (LJF), Large Male-Female (LMF), Small Male-Female (SMF), Large Tongue & Groove, Small Tongue, Groove. |

| Grade | |

| Stainless Steel | 200 Series – 201, 202, 205. 300 Series 301, 302, 303, 304, 304L, 308, 309, 309S, 310, 310S, 314, 316, 316L, 316TI, 317, 317L, 321, 347. 400 Series 405, 409, 429, 430, 430F, 430FSe, 434, 436, 442, 446, 403, 410, 414,416, 416Se, 420,420F, 422, 431, 440A, 440B, 440C. 500 Series – 501, 502. 600 Series – 630 (17-4 PH). |

| Carbon Steel | ASTM / ASME A105. ASTM / ASME A 350 LF 2 . |

| Alloy Steel | ASTM / ASME A 182 GR F 5, F 9 , F 11 , F 12 , F 22 , F 91. |

| Duplex / Super Duplex Steel | D S31803, D S32205, SD S32750, SD S32760, SD S32950. |

| Inconel | 601, 625, 660A, 718, X-750, 825, 925, 608. |

| Monel | 400, K500. |

| Hastelloy | C22, C276, X, B-2. |

Dimensions Chart Of Flanges:

The dimensions of flanges can vary depending on their type and size. In this chart, we will explore the different dimensions of flanges and provide a chart to help you choose the right flange for your needs.

| DN (inch) |

Dimension | ANSI B16.5 Flange Dimensional Sizes 3 to 10 inches Table Chart | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 125 lbs 150 lbs |

300 lbs | 400 lbs | 600 lbs | 900 lbs | 1500 lbs | 2500 lbs | ||||||||||

| inch | mm | inch | mm | inch | mm | inch | mm | inch | mm | inch | mm | inch | mm | |||

| 3 | A | 7 1/2 | 190.5 | 81/4 | 209.6 | 81/4 | 209.6 | 8 1/4 | 209.6 | 9 1/2 | 241 | 10 1/2 | 267 | 12 | 305 | |

| b | 15/16 | 23.8 | 1 1/8 | 28.6 | 11/4 | 31.8 | 1 1/4 | 31.8 | 1 1/2 | 38.1 | 1 7/8 | 47.6 | 2 5/8 | 66.7 | ||

| D2 | 5 | 127 | 5 | 127 | 5 | 127 | 5 | 127 | 5 | 127 | 5 | 127 | 5 | 127 | ||

| D1 | 6 | 152.4 | 6 5/8 | 168.3 | 6 5/8 | 168.3 | 6 5/8 | 168.3 | 71/2 | 190.5 | 8 | 203 | 9 | 228.6 | ||

| n | 4 | 4 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | ||

| d | 3/4 | 19 | 7/8 | 22.2 | 7/8 | 22.2 | 7/8 | 22.2 | 1 | 25.4 | 1 1/4 | 31.8 | 1 3/8 | 34.9 | ||

| 3 1/2 | A | 8 1/2 | 215.9 | 9 | 228.6 | 9 | 228.6 | 9 | 228.6 | – | – | – | – | – | – | |

| b | 15/16 | 23.8 | 13/16 | 30.2 | 13/8 | 34.9 | 13/8 | 34.9 | – | – | – | – | – | – | ||

| D2 | 5 1/2 | 139.7 | 5 /2 | 139.7 | 5 1/2 | 139.7 | 5 1/2 | 139.7 | – | – | – | – | – | – | ||

| D1 | 7 | 177.8 | 7 1/4 | 184.2 | 7 1/4 | 184.2 | 7 1/4 | 184.2 | – | – | – | – | – | – | ||

| n | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | – | – | – | – | – | – | ||

| d | 3/4 | 19 | 7/8 | 22.2 | 1 | 25.4 | 1 | 25.4 | – | – | – | – | – | – | ||

| 4 | A | 9 | 228.6 | 10 | 254 | 10 | 254 | 10 3/4 | 273 | 11 1/2 | 292 | 12 1/4 | 311 | 14 | 356 | |

| b | 15/16 | 23.8 | 1 1/4 | 31.7 | 1 3/8 | 34.9 | 1 1/2 | 38.1 | 1 3/4 | 44.4 | 2 1/8 | 54 | 3 | 76.2 | ||

| D2 | 6 3/16 | 157.2 | 6 3/16 | 157.2 | 6 3/16 | 157.2 | 6 3/16 | 157.2 | 6 3/16 | 157.2 | 6 3/16 | 157.2 | 6 3/16 | 157.2 | ||

| D1 | 7 1/2 | 190 | 7 7/8 | 200 | 7 7/8 | 200 | 8 1/2 | 215.9 | 9 1/4 | 235 | 9 1/2 | 241 | 10 3/4 | 273 | ||

| n | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | ||

| d | 3/4 | 19 | 7/8 | 22.2 | 1 | 25.4 | 1 | 25.4 | 1 1/4 | 31.8 | 1 3/8 | 34.9 | 1 5/8 | 41.3 | ||

| 5 | A | 10 | 254 | 11 | 279.4 | 11 | 279.4 | 13 | 330.2 | 13 3/4 | 349 | 14 3/4 | 375 | 16 1/2 | 419 | |

| b | 1 5/16 | 23.8 | 13/8 | 34.9 | 1 1/2 | 38.1 | 1 3/4 | 44.4 | 2 | 50.8 | 2 7/8 | 73 | 3 5/8 | 92.1 | ||

| D2 | 7 5/16 | 185.7 | 7 5/16 | 185.7 | 7 5/16 | 185.7 | 7 5/16 | 185.7 | 7 5/16 | 185.7 | 7 5/16 | 185.7 | 7 5/16 | 185.7 | ||

| D1 | 8 1/2 | 215.9 | 9 1/4 | 234.9 | 9 1/4 | 234.9 | 10 1/2 | 266.7 | 11 | 279 | 11 1/2 | 292 | 12 3/4 | 324 | ||

| n | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | ||

| d | 7/8 | 22.2 | 7/8 | 22.2 | 1 | 25.4 | 1 1/8 | 28.6 | 1 3/8 | 34.9 | 1 5/8 | 41.3 | 1 7/8 | 47.6 | ||

| 6 | A | 11 | 279 | 12 1/2 | 317.5 | 12 1/2 | 317.5 | 14 | 355.6 | 15 | 381 | 15 1/2 | 394 | 19 | 483 | |

| b | 1 | 25.4 | 17/16 | 36.5 | 1 5/8 | 41.3 | 1 7/8 | 47.6 | 2 3/16 | 55.6 | 3 1/4 | 82.6 | 4 1/4 | 108 | ||

| D2 | 8 1/2 | 216 | 8 1/2 | 215.9 | 8 1/2 | 215.9 | 8 1/2 | 215.9 | 8 1/2 | 215.9 | 8 1/2 | 215.9 | 8 1/2 | 216 | ||

| D1 | 9 1/2 | 241 | 10 5/8 | 269.9 | 10 5/8 | 269.9 | 11 1/2 | 292.1 | 12 1/2 | 318 | 12 1/2 | 318 | 14 1/2 | 368 | ||

| n | 8 | 8 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 8 | 8 | ||

| d | 7/8 | 22.2 | 7/8 | 22.2 | 1 | 25.4 | 1 1/8 | 28.6 | 1 1/4 | 31.8 | 1 1/2 | 38.1 | 2 1/8 | 54 | ||

| 8 | A | 13 1/2 | 342.9 | 15 | 381 | 15 | 381 | 16 1/2 | 419 | 18 1/2 | 470 | 19 | 482.6 | 21 3/4 | 552 | |

| b | 1 1/8 | 28.6 | 1 5/8 | 41.3 | 1 7/8 | 47.6 | 2 3/16 | 55.6 | 2 1/2 | 63.5 | 3 5/8 | 92.1 | 5 | 127 | ||

| D2 | 10 5/8 | 269.9 | 10 5/8 | 269.9 | 10 5/8 | 269.9 | 10 5/8 | 269.9 | 10 5/8 | 269.9 | 10 5/8 | 269.9 | 10 5/8 | 269.9 | ||

| D1 | 11 3/4 | 298.4 | 13 | 330.2 | 13 | 330.2 | 13 3/4 | 349.2 | 15 1/2 | 394.2 | 15 1/2 | 394.2 | 17 1/4 | 438 | ||

| n | 8 | 8 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | ||

| d | 7/8 | 22.2 | 1 | 25.4 | 1 1/8 | 28.6 | 1 1/4 | 31.8 | 1 1/2 | 38.1 | 1 3/4 | 44.5 | 2 1/8 | 54 | ||

| 10 | A | 16 | 406.4 | 17 1/2 | 444.5 | 17 1/2 | 444.5 | 20 | 508 | 21 1/2 | 546 | 23 | 584 | 26 1/2 | 673 | |

| b | 1 3/16 | 30.2 | 1 7/8 | 47.6 | 2 1/8 | 54 | 2 1/2 | 63.5 | 2 3/4 | 69.8 | 4 1/4 | 108 | 6 1/2 | 165 | ||

| D2 | 12 3/4 | 323.8 | 12 3/4 | 323.8 | 12 3/4 | 323.8 | 12 3/4 | 323.8 | 12 3/4 | 323.8 | 12 3/4 | 323.8 | 12 3/4 | 323.8 | ||

| D1 | 14 1/4 | 361.9 | 15 1/4 | 387.4 | 15 1/4 | 387.4 | 17 | 431.8 | 18 1/2 | 470 | 19 | 482.6 | 21 1/4 | 540 | ||

| n | 12 | 12 | 16 | 16 | 16 | 16 | 16 | 16 | 16 | 16 | 12 | 12 | 12 | 12 | ||

| d | 1 | 25.4 | 1 1/8 | 28.6 | 1 1/4 | 31.8 | 1 3/8 | 34.9 | 1 1/2 | 38.1 | 2 | 50.8 | 2 5/8 | 66.7 | ||

Client Projects for Flanges Supplier in Wada MIDC India:

Flanges are used in exotic as well as high-demanding applications such as Jet Engine Turbine Blades, Spacecraft, & Nuclear Reactors. Flanges are a well-known product in the metal industry, and Kanak Metal & Alloys is a leading Flanges manufacturer and supplier.

| Products | Cities/ States |

|---|---|

| Flanges Supplied to Paper Mill | Wada MIDC, India |

| Slip-On Flanges Supplied to Power Plants | Coimbatore |

| Blind Flanges Supplied to Chemical Industry | Pune, Maharashtra |

| Flanges Suppliers | Vijaywada, Hyderabad |

Application & Uses of Flanges:

- Sugar Industry

- Power Industry

- Shipbuilding Industry

- Mechanical and Plant Engineering

- Food, Beverage, and Dairy

- Oil and Gas Plant

- Process Instrumentation

Flanges Additional Information:

Kanak Metal & Alloys uses optimal packaging methods, such as special 4-layer packaging for exports. The packaging procedure ensures that the materials arrive in perfect condition. Flanges are used in a variety of industries, including sugar, nuclear, marine, and defense.

- Payment Modes: LC (Letter of Credit), TT (Telegraphic Transfer or Wire Transfer), Cheque, and others.

- Packaging: Flanges are packaged with caution and safety so they reach our client’s as good as they would expect. Packaging Charges Extra.

- Port of Dispatch: Mumbai ports in the Maharashtra state of India.

- Tax: 18% GST.

Cities We Supply Flanges

Kanak Metal & Alloys is a global supplier and dealer of Flanges, offering a wide range of products. Our highly efficient supply procedure complies with global quality standards, allowing us to maintain our position as a top-tier Flanges manufacturer & supplier. As a result, our supply network has expanded to include cities such as Bengaluru, Mumbai, Chennai, Hyderabad, Kolkata, Pune, and Delhi.

Flanges We Export in Various Countries:

Kanak Metal & Alloys is a well-known company that offers various types of Flanges. We supply Flanges products to customers in India and around the world, including the United States, the Germany, Australia, and others. We offer Flanges at a reasonable price to our customers.

Pipe Fittings Supplier in Saudi Arabia

Pipe Fittings Supplier in Saudi Arabia Pipe Fittings Supplier in Oman

Pipe Fittings Supplier in Oman Pipe Fittings Supplier in Kuwait

Pipe Fittings Supplier in Kuwait Pipe Fittings Supplier in Netherlands

Pipe Fittings Supplier in Netherlands Pipe Fittings Supplier in Iran

Pipe Fittings Supplier in Iran Pipe Fittings Supplier in Bahrain

Pipe Fittings Supplier in Bahrain Pipe Fittings Supplier in Qatar

Pipe Fittings Supplier in Qatar Pipe Fittings Supplier in UAE

Pipe Fittings Supplier in UAE Pipe Fittings Supplier in South Korea

Pipe Fittings Supplier in South Korea Pipe Fittings Supplier in Benin

Pipe Fittings Supplier in Benin Pipe Fittings Supplier in Nigeria

Pipe Fittings Supplier in Nigeria Pipe Fittings Supplier in Venezuela

Pipe Fittings Supplier in Venezuela Pipe Fittings Supplier in Mexico

Pipe Fittings Supplier in Mexico Pipe Fittings Supplier in Canada

Pipe Fittings Supplier in Canada Pipe Fittings Supplier in United Kingdom

Pipe Fittings Supplier in United Kingdom Pipe Fittings Supplier in United States

Pipe Fittings Supplier in United States Pipe Fittings Supplier in Malaysia

Pipe Fittings Supplier in Malaysia Pipe Fittings Supplier in South Africa

Pipe Fittings Supplier in South Africa Pipe Fittings Supplier in Bangladesh

Pipe Fittings Supplier in Bangladesh Pipe Fittings Supplier in Turkey

Pipe Fittings Supplier in Turkey Pipe Fittings Supplier in Singapore

Pipe Fittings Supplier in Singapore Pipe Fittings Supplier in Sri Lanka

Pipe Fittings Supplier in Sri Lanka Pipe Fittings Supplier in Australia

Pipe Fittings Supplier in Australia Pipe Fittings Supplier in Brazil

Pipe Fittings Supplier in Brazil Pipe Fittings Supplier in Europe

Pipe Fittings Supplier in Europe